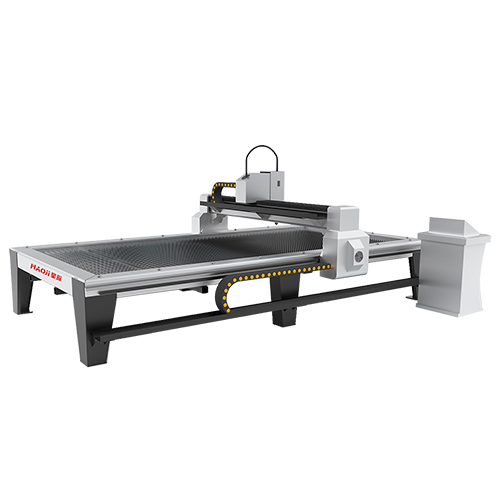

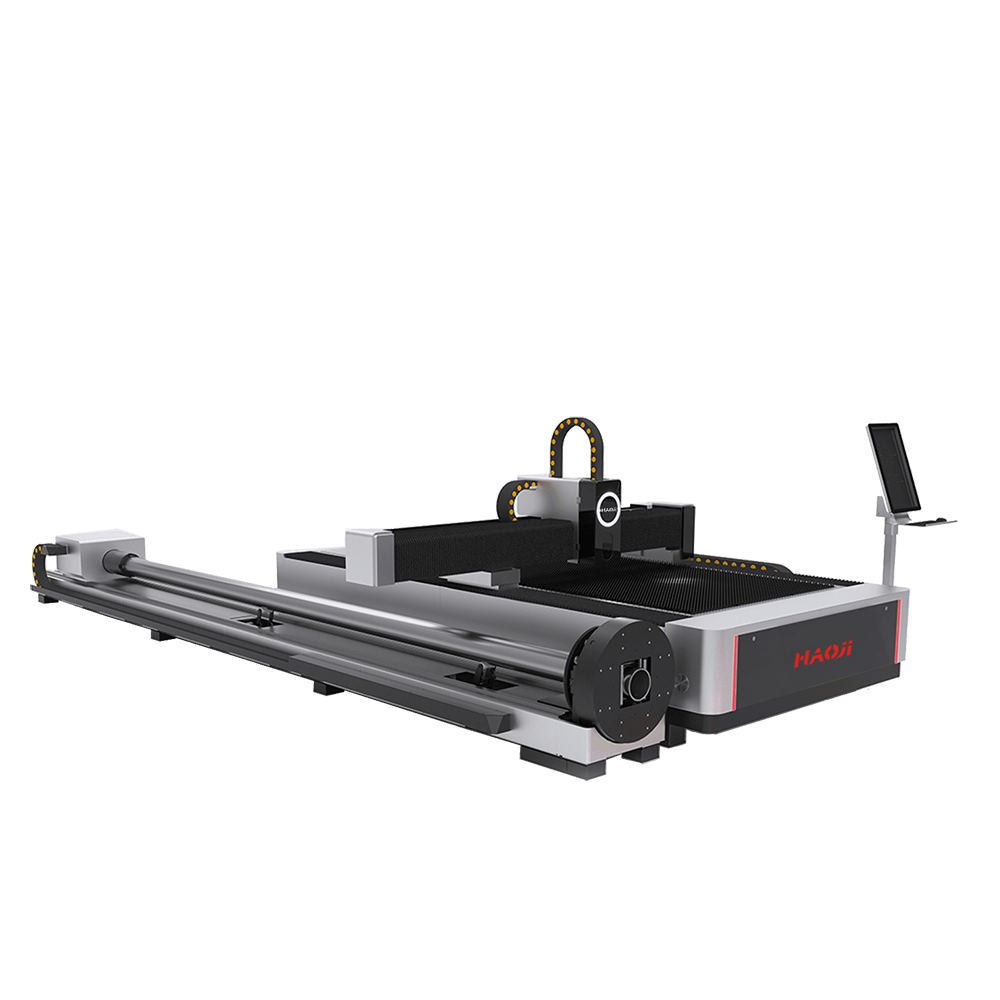

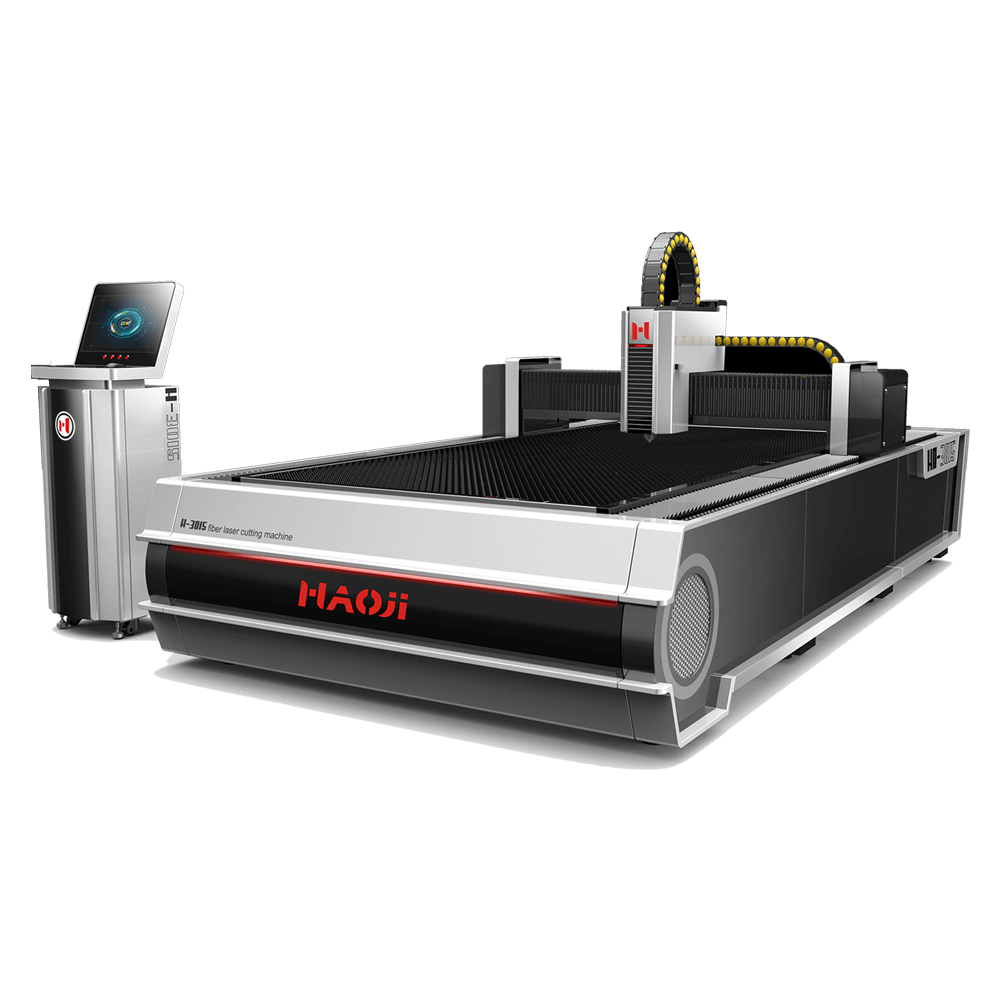

Laser power

1000~20000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

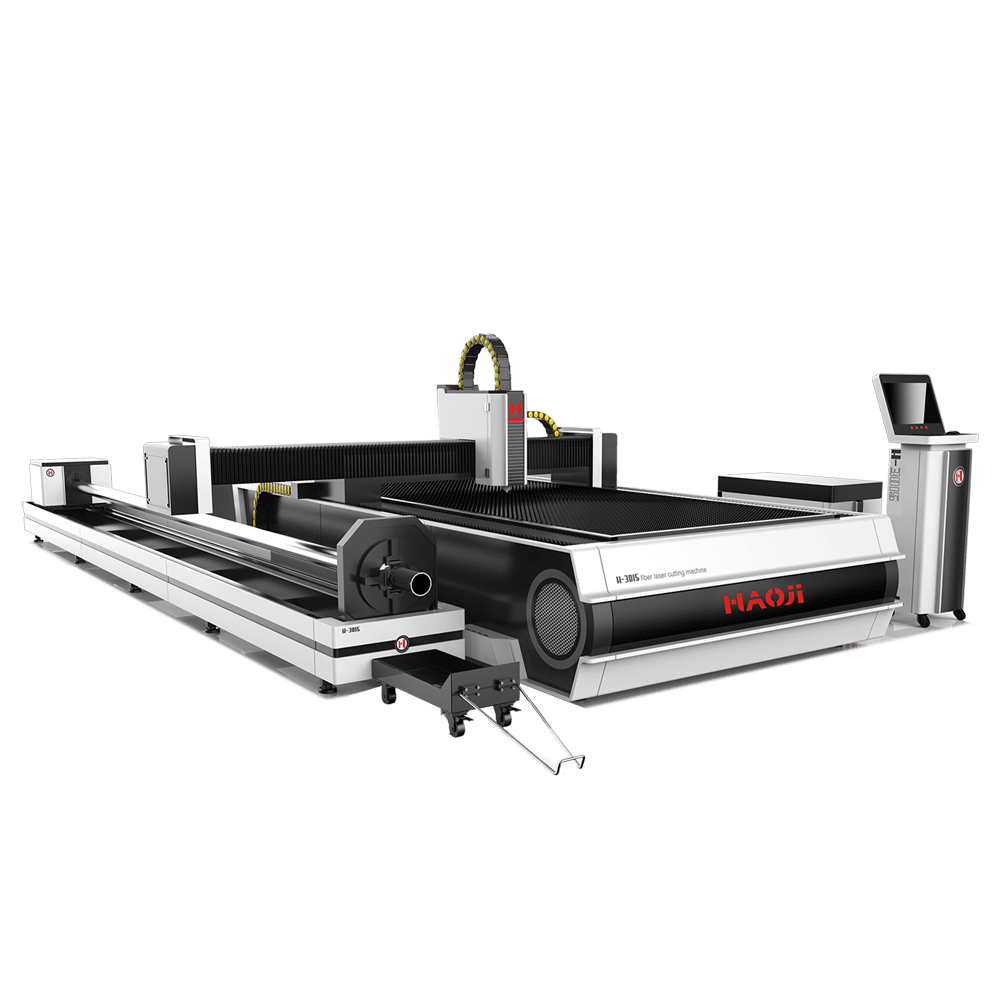

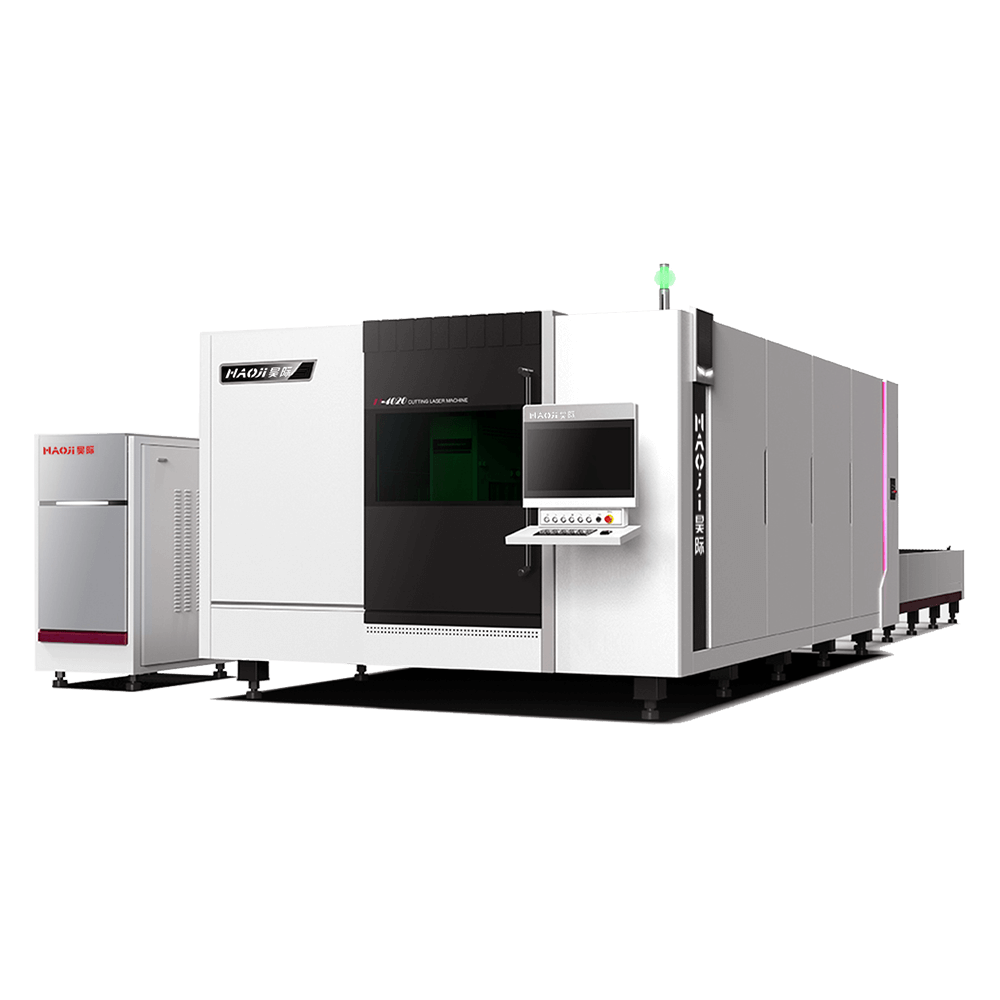

Laser power

1000~20000wMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

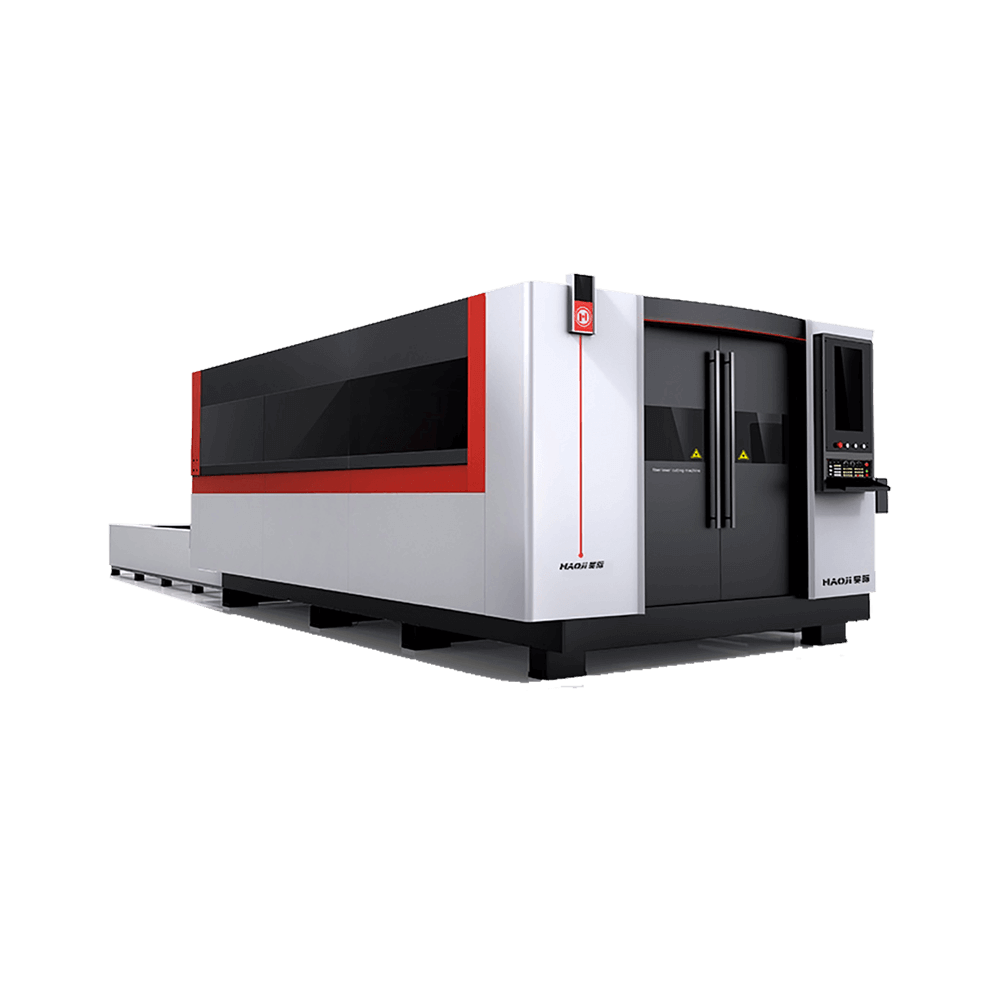

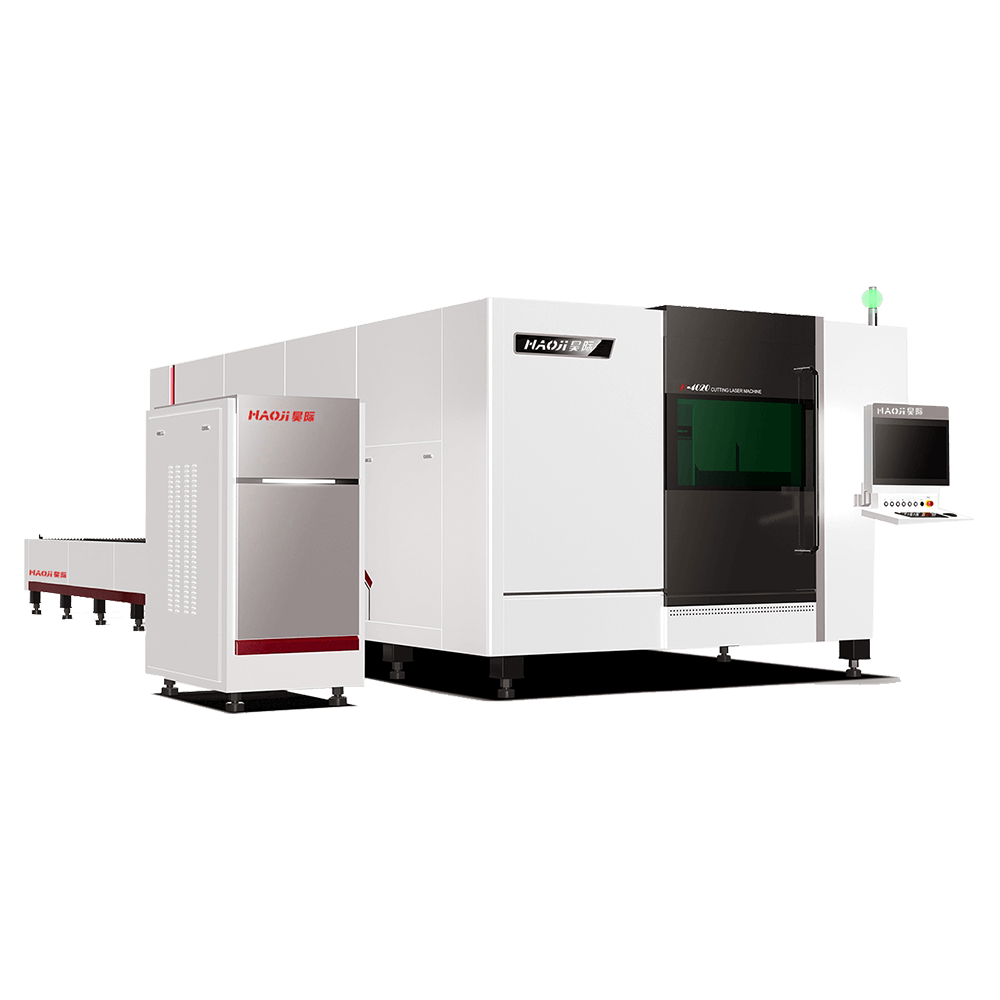

Laser power

1000~20000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

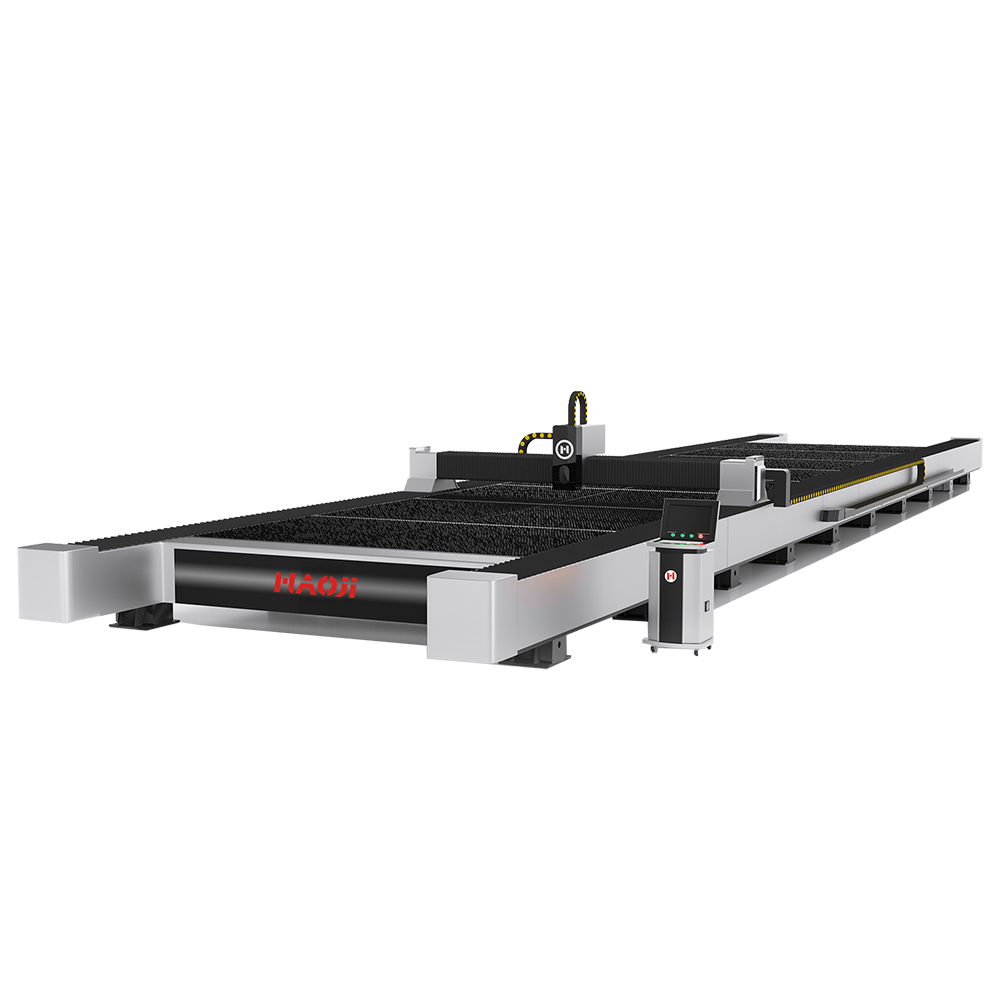

Laser power

10000-35000WMax. moving speed

200m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-20000WMax. moving speed

200m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-12000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

3000-20000WMax. moving speed

180m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

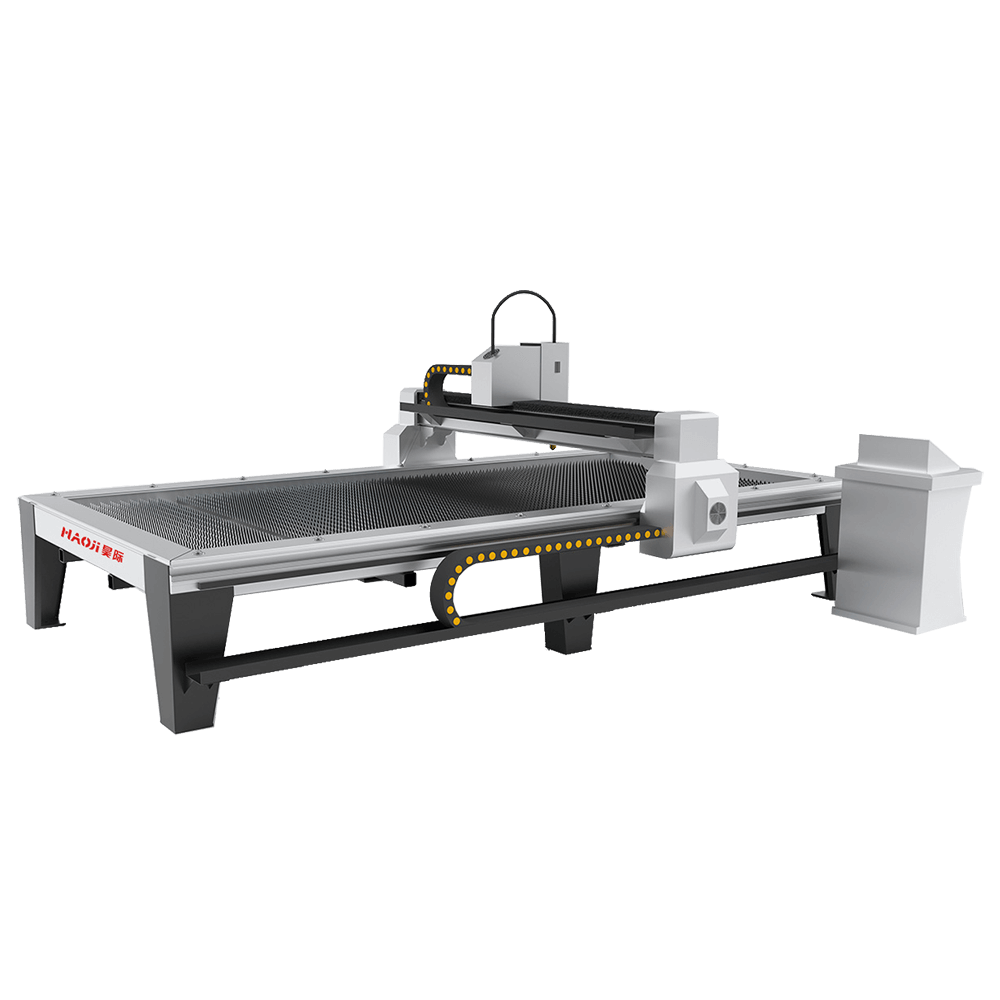

Laser power

/Max. moving speed

100m/minRepeat positioning accuracy

0.03mmBlessing diameter

/

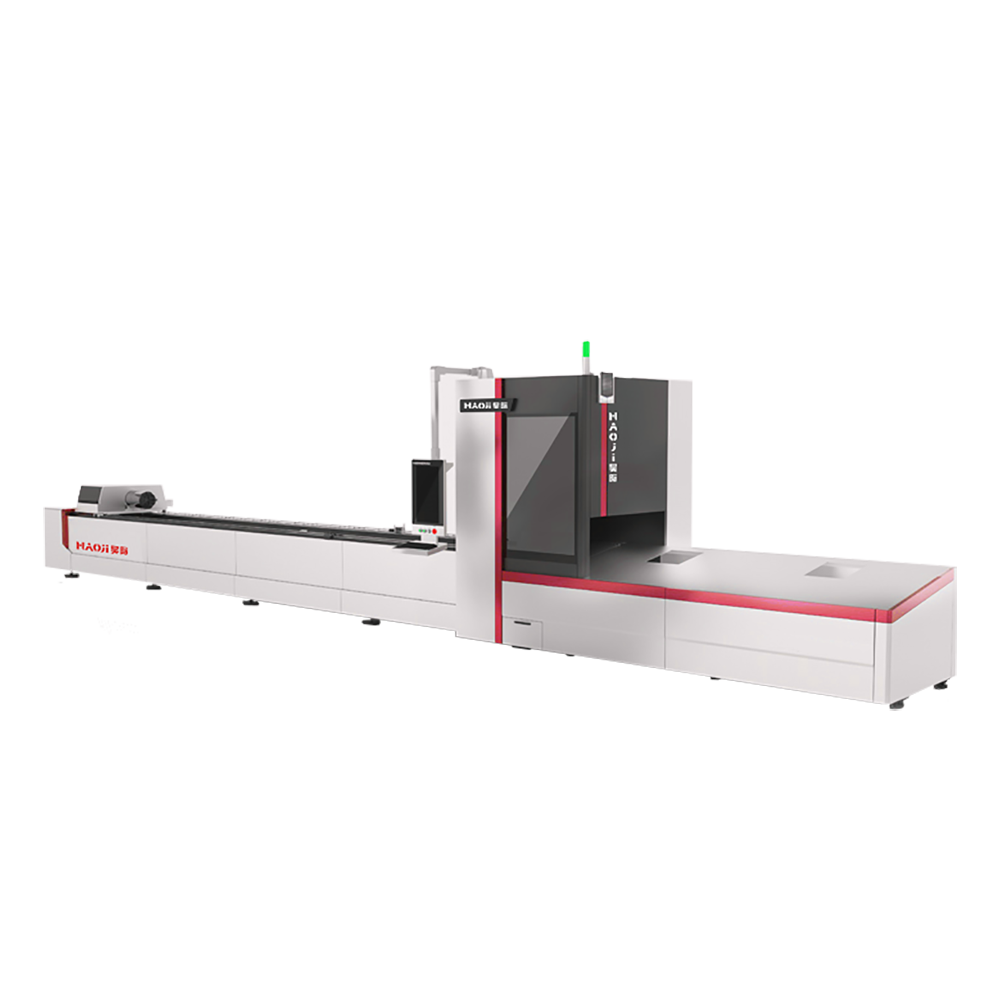

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

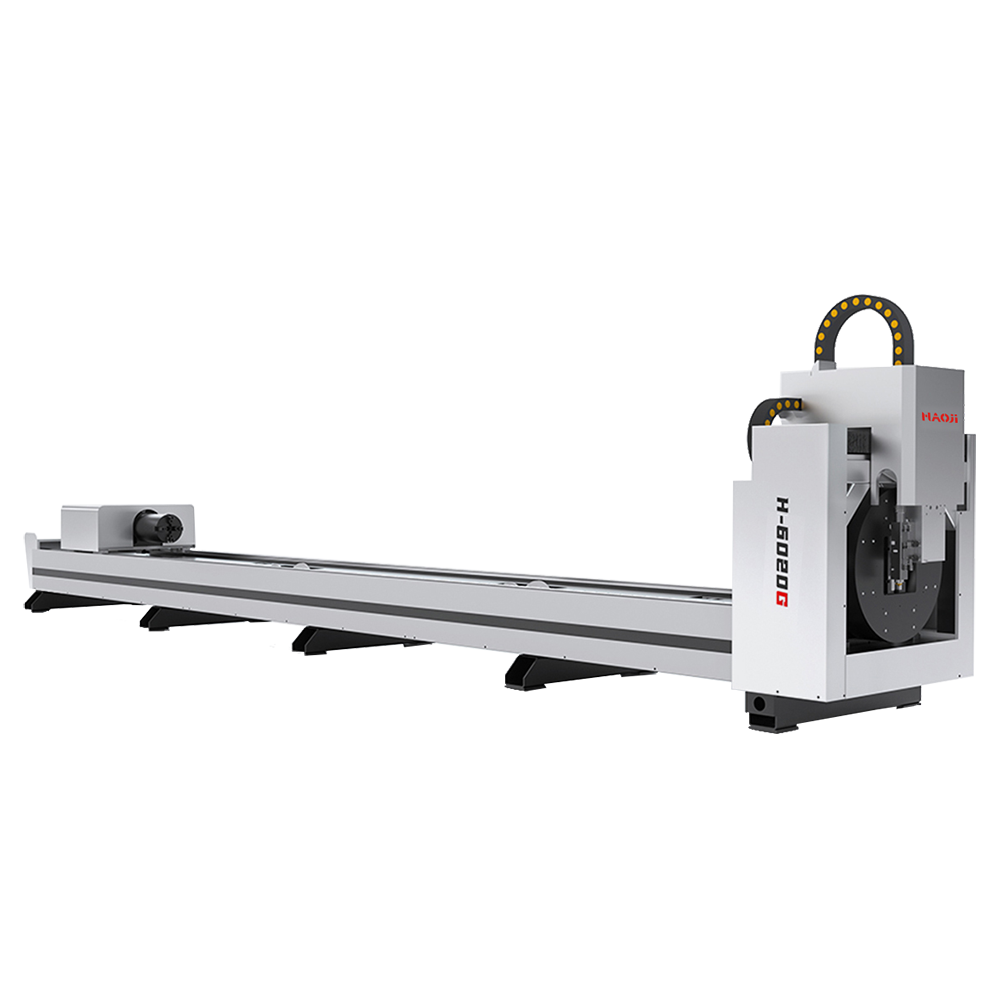

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

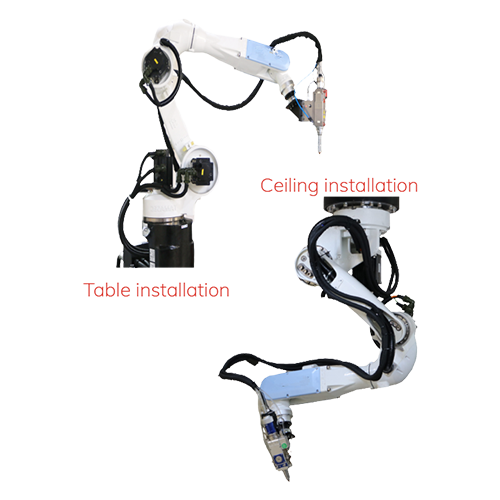

Laser power

1000W-4000WMax. moving speed

140°-600°/sRepeat positioning accuracy

±0.1mmBlessing diameter

/

Laser power

1000-3000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-2000WMax. moving speed

/Repeat positioning accuracy

/Blessing diameter

/

Laser power

/Max. moving speed

/Repeat positioning accuracy

/Blessing diameter

/

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

TIME:07-14 2021

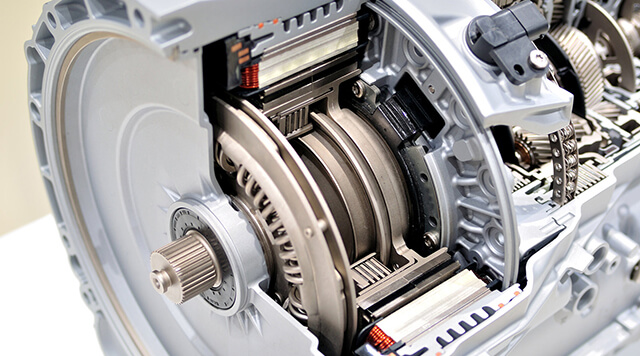

Automotive companies around the world are facing strict emission and fuel economy regulations. So many countries are already on the way to widespread adoption of new energy vehicle.

NEVs with the slogan of green commuting, safety and environmental protection are accepted by more and more consumers

Someone said "The time is now for NEVs and the shift could be faster than anybody predicted"

As a new type of vehicle, NEVs are developing rapidly, and they are bound to become a new development trend in the future automotive market

In order to meet the requirements of automobile lightweight, some new materials and processing methods have emerged and expanded the scope of application

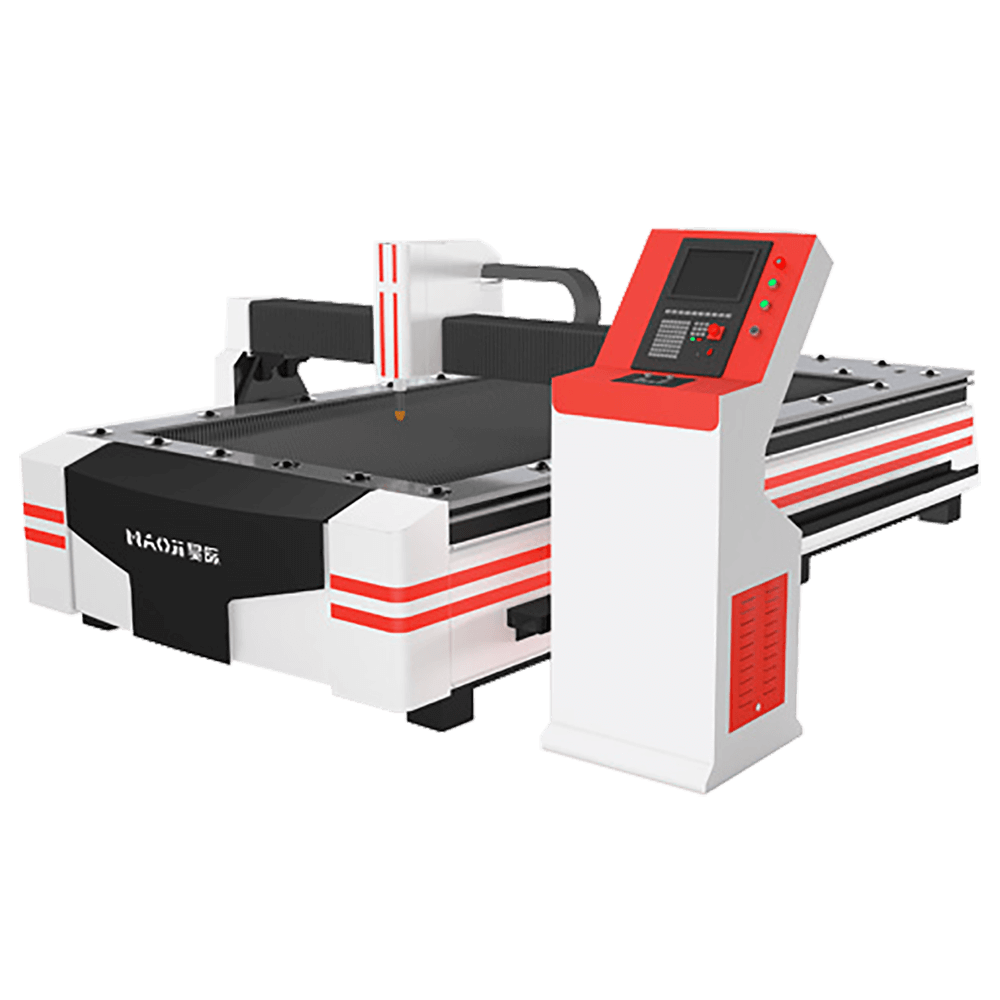

At present, some of the lightweight structural parts in our automobile industry are produced by laser cutting machines for zero-contact processing. During the processing, the laser cutting processing can achieve all kinds of cutting without touching the product. And can meet the requirements of precision and robustness in automobile manufacturing

Laser cutting is one of the main laser applications. laser cutting processing in the automobile industry includes flat sheet cutting and 3D cutting

The application range of flat sheet cutting includes: automobile parts, automobile body, doors, trunk lid, roof cover, outerhood and other aspects

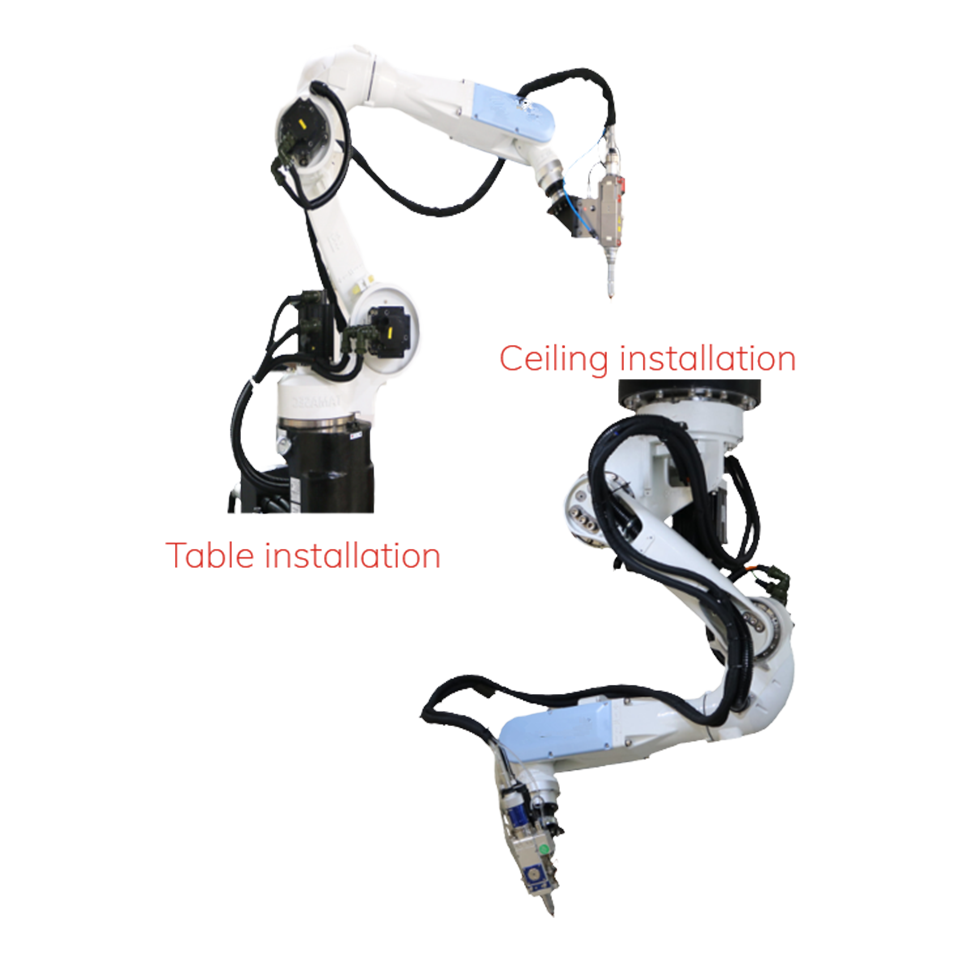

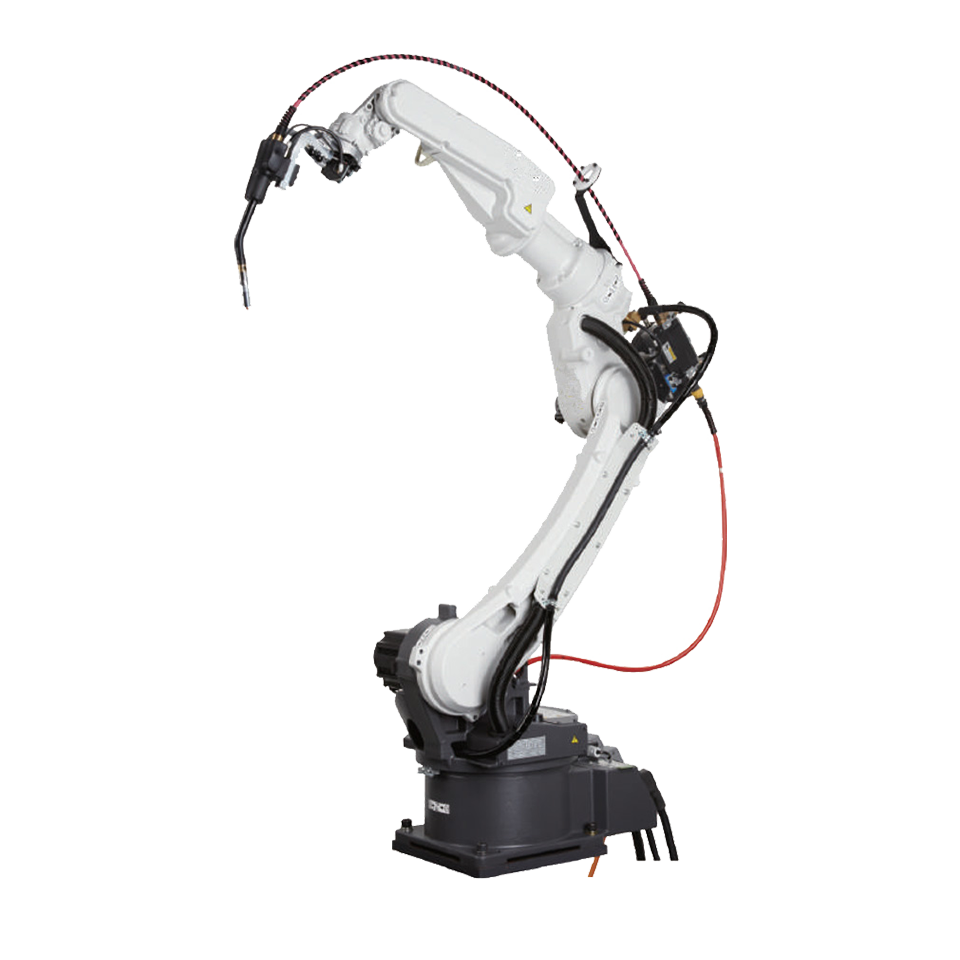

The application of 3D laser cutting processing is mainly in the design and manufacture of automobile bodywork. It is widely used in the development of new models, cutting holes for body panels, trimming, cutting steering wheel holes, windshields, roof cover brackets, etc.

Haoji Technology strives to promote the application of laser cutting processing in new energy vehicles, and provides solutions to help companies improve production efficiency, process levels, quickly respond to market changes, and enhance the competitiveness of new energy vehicles in the automotive market